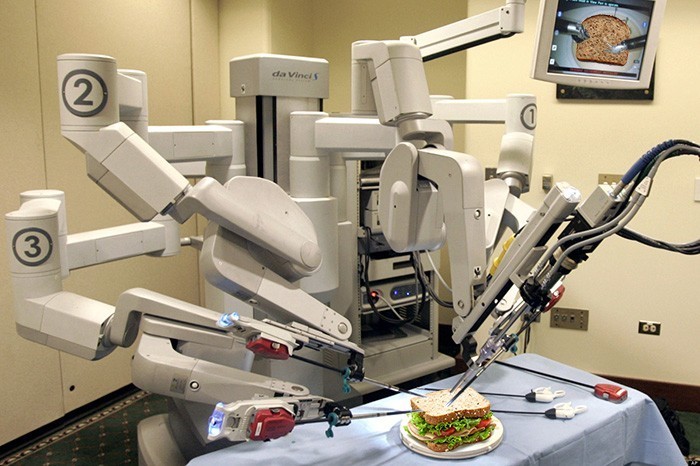

CLEVELAND, OH – After finishing up his cases for the day, an oncological surgeon brought sandwich supplies with him to a vacant operating room and began setting up a sterile field. “I’ve always wanted to do this,” said the veteran surgeon as he positioned the 4 arm $1.5 million piece of machinery over 2 pieces of whole grain bread, 4 slices of Virginia ham, 2 pieces of provolone cheese, 2 fresh tomato slices, several pieces of lettuce, and a container of Grey Poupon mustard.

As he sat at the da Vinci control station and admired the three-dimensional view of his ingredients, he began to drool, carelessly allowing saliva to drip onto his scrubs. “11 hours since I’ve eaten anything, but this’ll make up for it,” he muttered to himself as he excitedly began assembling his sandwich with a robotic instrument system that represents the pinnacle of modern surgical technology.

“Right from the get go I knew the da Vinci’s minimally invasive approach had clear applications for sandwich construction. I wasn’t surprised to read that the technique was eventually shown to be correlated with increases in post prandial consumer satisfaction as well as improved long term digestive outcomes.”

With two da Vinci arms, he precisely stacked the ham, cheese, lettuce, and tomato slices on one whole grain bread slice before using the other two arms to handle the Poupon container and a scalpel to spread its contents evenly over the second bread slice.

“Now for the best part,” the surgeon said, as he manipulated the cauterizer so as to divide the three-dimensional square sandwich image into two irresistible triangular halves. “The only drawback is not being able to use the da Vinci to actually eat the sandwich. Well that and the fact that this took me eight times as long as the traditional method, but at least I had fun.”